Revolutionizing Rubber Technologies The Impact of Carbon Nanotubes and Graphene

Revolutionizing Rubber Technologies: The Impact of Carbon Nanotubes and Graphene

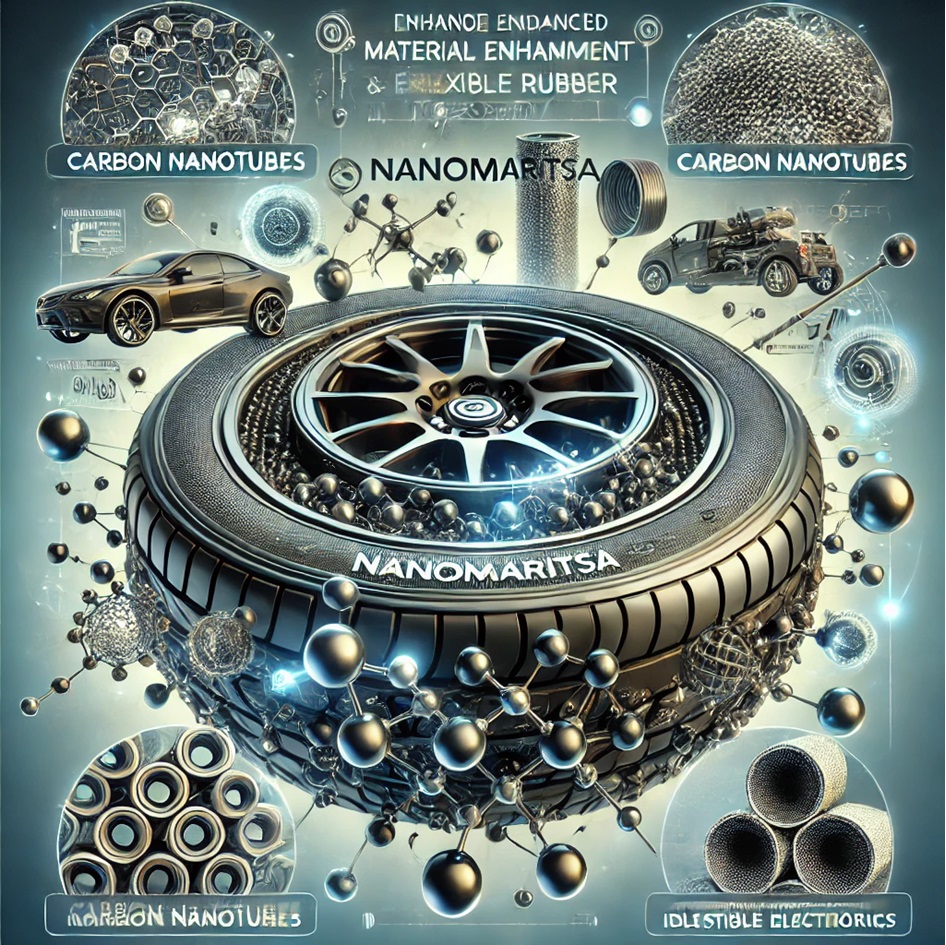

Rubber has long been a cornerstone material in industries such as automotive, aerospace, and manufacturing. The integration of advanced nanomaterials like carbon nanotubes (CNTs) and graphene is reshaping the landscape of rubber technologies, offering unprecedented improvements in strength, durability, conductivity, and sustainability. This blog explores the transformative applications of CNTs and graphene in rubber technologies, backed by the latest research and industrial advancements.

Why Use Carbon Nanotubes and Graphene in Rubber?

Carbon nanotubes and graphene introduce a new realm of possibilities for enhancing rubber properties. Their nanoscale dimensions and exceptional physical and chemical characteristics make them ideal for rubber composites.

Key Benefits:

- Mechanical Reinforcement: Significant improvement in tensile strength, elasticity, and wear resistance.

- Thermal Conductivity: Efficient heat dissipation for high-performance applications.

- Electrical Conductivity: Enables antistatic and conductive properties.

- Chemical Resistance: Enhanced durability against oils, chemicals, and environmental degradation.

- Sustainability: Reduces the reliance on non-renewable additives.

Applications of CNTs and Graphene in Rubber Technologies

- Automotive Tires

- Challenge:

- Modern tires require a balance of durability, fuel efficiency, and grip.

- Solution:

- Incorporating CNTs and graphene into rubber compounds enhances wear resistance, reduces rolling resistance, and improves traction. These features contribute to fuel efficiency and prolonged tire lifespan.

- Industrial Belts and Hoses

- Challenge:

- High mechanical stress and chemical exposure reduce the lifespan of industrial components.

- Solution:

- CNT and graphene-reinforced rubber offers superior tensile strength and chemical resistance, ensuring durability in demanding environments.

- Seals and Gaskets

- Challenge:

- Maintaining sealing integrity under extreme temperatures and pressures.

- Solution:

- Nanomaterial-enhanced rubber improves resilience and maintains performance in harsh conditions.

- Conductive Rubber for Electronics

- Challenge:

- Traditional rubber lacks electrical conductivity for advanced electronic applications.

- Solution:

- CNTs and graphene impart conductivity, enabling applications such as antistatic components and flexible electronic devices.

- Thermal Management Systems

- Challenge:

- Effective heat dissipation is critical in automotive and industrial systems.

- Solution:

- Graphene’s high thermal conductivity enhances the performance of heat-resistant rubber materials.

Recent Innovations in Nanomaterial-Enhanced Rubber

- Self-Healing Rubber:

- Nanomaterial-infused rubber composites with self-healing properties are being developed to extend the lifespan of products and reduce maintenance costs.

- Sustainable Alternatives:

- Replacing carbon black with graphene as a reinforcing agent reduces the environmental impact of rubber production.

- Advanced Tread Patterns:

- Graphene-infused rubber enables the development of high-performance tread patterns with improved grip and wear resistance.

- Flexible and Wearable Electronics:

- Conductive rubber composites are paving the way for flexible sensors and wearable technologies.

Challenges in Adoption

- Cost of Nanomaterials:

- The high cost of CNTs and graphene remains a barrier for widespread industrial use.

- Dispersion Techniques:

- Achieving uniform dispersion of nanomaterials in rubber matrices is challenging.

- Scalability:

- Scaling up production while maintaining quality and performance requires further innovation.

- Compatibility:

- Ensuring compatibility with existing manufacturing processes is crucial for seamless integration.

Future Directions

- Hybrid Nanocomposites:

- Combining CNTs and graphene with other materials to create multifunctional rubber composites.

- Smart Rubber Technologies:

- Developing rubber with embedded sensors for real-time monitoring and feedback.

- Eco-Friendly Solutions:

- Expanding the use of renewable and recyclable nanomaterial-enhanced rubber.

- Advanced Manufacturing:

- Investing in advanced manufacturing techniques such as 3D printing for customized rubber products.

Conclusion

Carbon nanotubes and graphene are revolutionizing rubber technologies, offering unmatched enhancements in performance and sustainability. From automotive tires to flexible electronics, their integration into rubber composites is unlocking new possibilities across industries. As research progresses and manufacturing techniques advance, the synergy of CNTs and graphene will continue to drive innovation, shaping a future of smarter, more efficient materials.